| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Xrido

Model Number : 1600 and Customizable

Certification : CE ISO TUV

MOQ : 1 set

Payment Terms : Negotiable

Delivery Time : 2-30 Working Days

place of origin : Henan, China

video outgoing-inspection : Provided

machinery test report : Provided

core components : PLC, Engine, Bearing, Gearbox, Pressure vessel, motor, Gear, Pump

brand name : Xrido

warranty : 1 Year

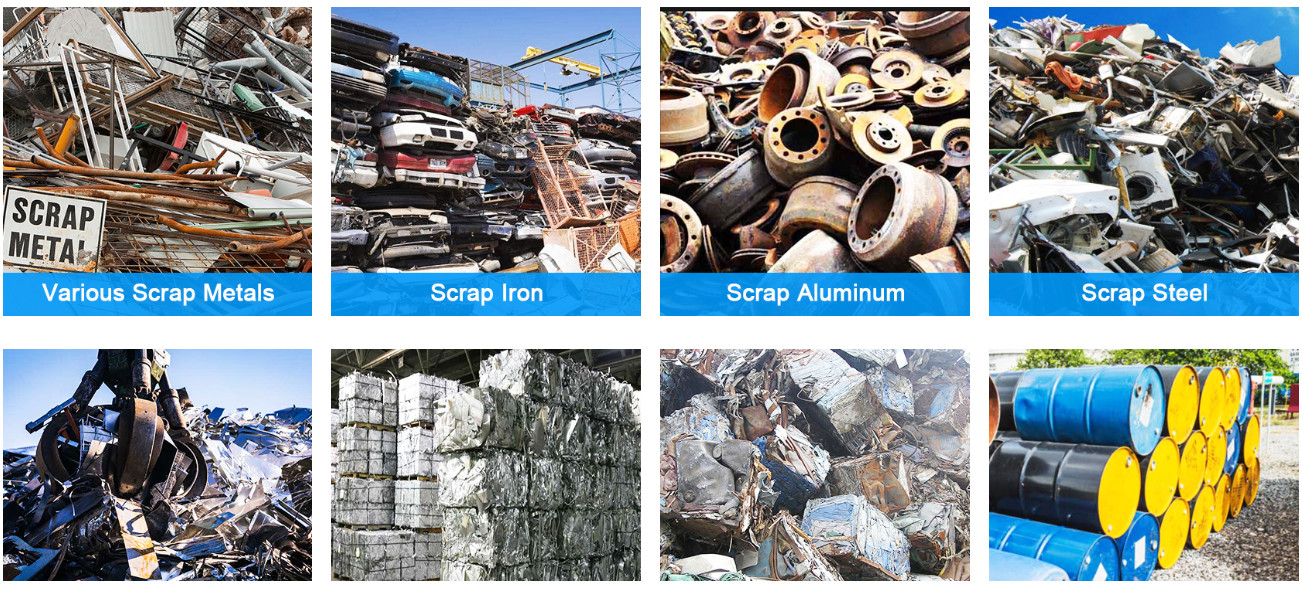

material / metal processed : Stainless Steel, Brass / Copper, Alloy, Carbon Steel, Aluminum

key selling points : Competitive Price

Product name : Waste Shredder Machine

Advantage : Easy Operation High Efficiency

Machine Type : Support Customization

Output : Compact

Final product : 1-10 Cm

MOTOR : Famouse Brand

Application : Metal Plastic Wood Bottle Film

After-sales Service Provided : Video Technical Support

Condition : New

Marketing Type : Ordinary Product

Warranty of core components : 1 Year

Applicable Industries : Machinery Repair Shops, Building Material Shops, Manufacturing Plant

Scrap Metal Briquettes Shredder Scrap Metal Processing Plant Scrap Metal Recycling Shredder

Working principle of scrap metal briquetting shredder:

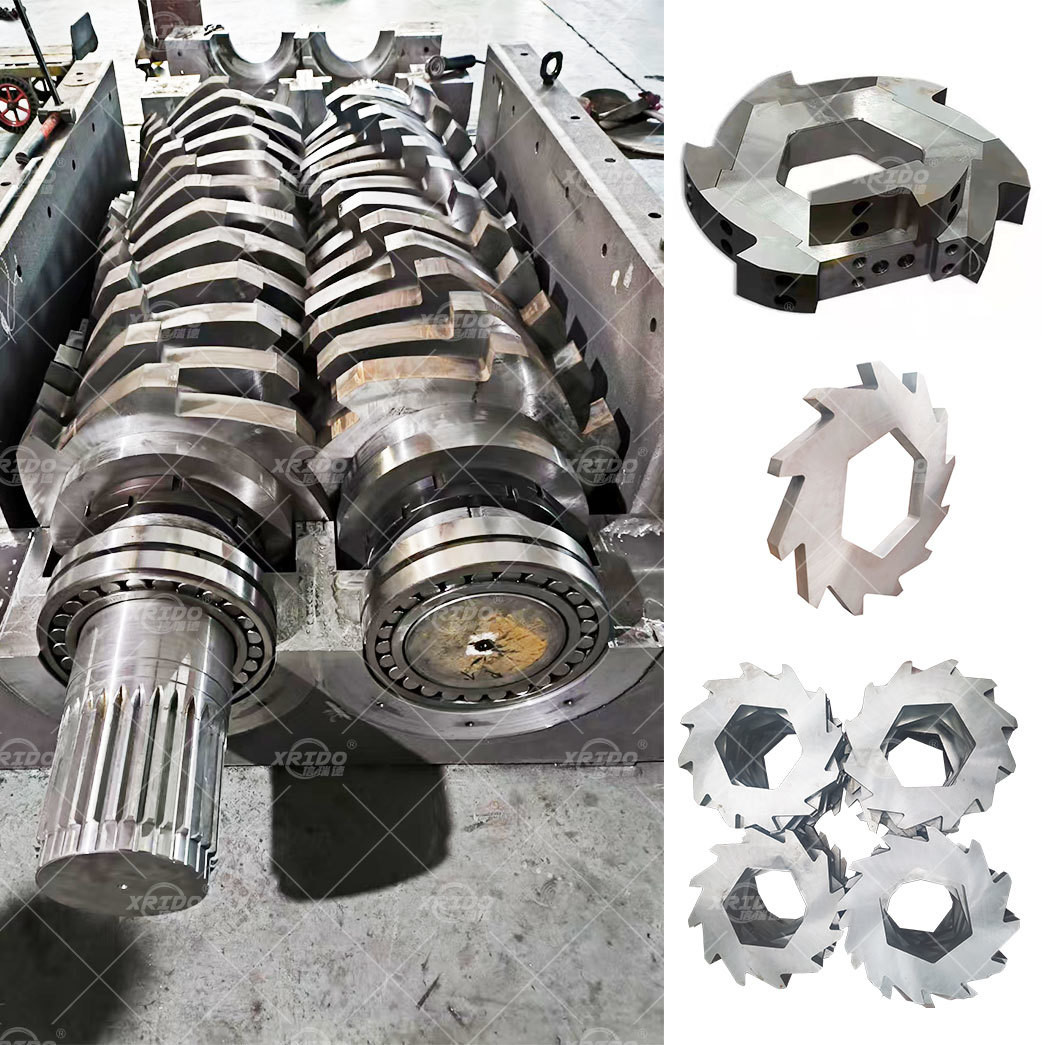

Dual spindle system: two parallel mounted spindles (speed 10-30rpm), with detachable blades arranged in a spiral line on the shaft;

Hydraulic pressing device: located behind the feed port, the briquetting material is pushed to the blade bite area by a hydraulic cylinder to ensure continuous feeding;

Power system: equipped with a high-power motor (usually 100-300kW) and a planetary gearbox to provide high torque output (up to 100,000 Nm).

|

|  |

| model | size(mm) | Shredder room(mm) | Blads(mm) | motor(k) | weight(kg) |

| XD-600 | 2800×1300×1850 | 600×480 | 200 | 11×2 | 2200 |

| XD-800 | 3000×1300×1850 | 800×480 | 200 | 15×2 | 2500 |

| XD-1000 | 3300×1900×2200 | 1000×690 | 300 | 22×2 | 5200 |

| XD-1200 | 3600×2000×2200 | 1200×690 | 300 | 30×2 | 6400 |

| XD-1500 | 4180×2100×2400 | 1500×850 | 550 | 55×2 | 9000 |

| XD-1800 | 5800×2400×3300 | 1800×1206 | 550 | 75×2 | 13600 |

| XD-2000 | 6400×2700×3500 | 2000×1490 | 600 | 90×2 | 20100 |

| XD-2500 | 7500×3200×3800 | 2500×1800 | 600 | 110×2 | 25000 |

| Notes: 1. The number of blade claws, diameter, and thickness can be customized according to the type of material and the size of the discharge. 2. The output of the equipment will be different depending on the type of material and the size of the discharge. 3. More information please contact us, we can custom the product on your request. | |||||

Advantages of scrap metal briquetting shredder:

Material adaptability: specializes in breaking high-density briquetting (density ≥2.5t/m³), such as steel shavings briquetting and aluminum chips briquetting.

Crushing efficiency: processing capacity 5-20 tons/hour (depending on the density of the briquetting), energy consumption ≤15kWh/ton.

Discharge uniformity: particle size deviation ≤±5mm, meeting the particle size requirements of smelting raw materials.

Equipment loss: blade wear is concentrated on the cutting edge, and the replacement cost is low.

Environmental protection features: fully enclosed cavity + soundproof cover, dust emission ≤20mg/m³, noise ≤80dB.

|

|

|

|

|

|

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

|

|

|

| Water Radiator Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

Reliable and durable recycling technologies for material separation and recovery,treatment of various types of solid waste and metal scrap. Metal recycling can benefit your Enhance and economic value , Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of mind through seamless maintenance and reduced downtime.

|

|

|

|

|

|

|

|  |

|

|

Scrap Metal Briquettes Shredder Scrap Metal Processing Plant Scrap Metal Recycling Shredder Images |